Raw Material Verification Reliability

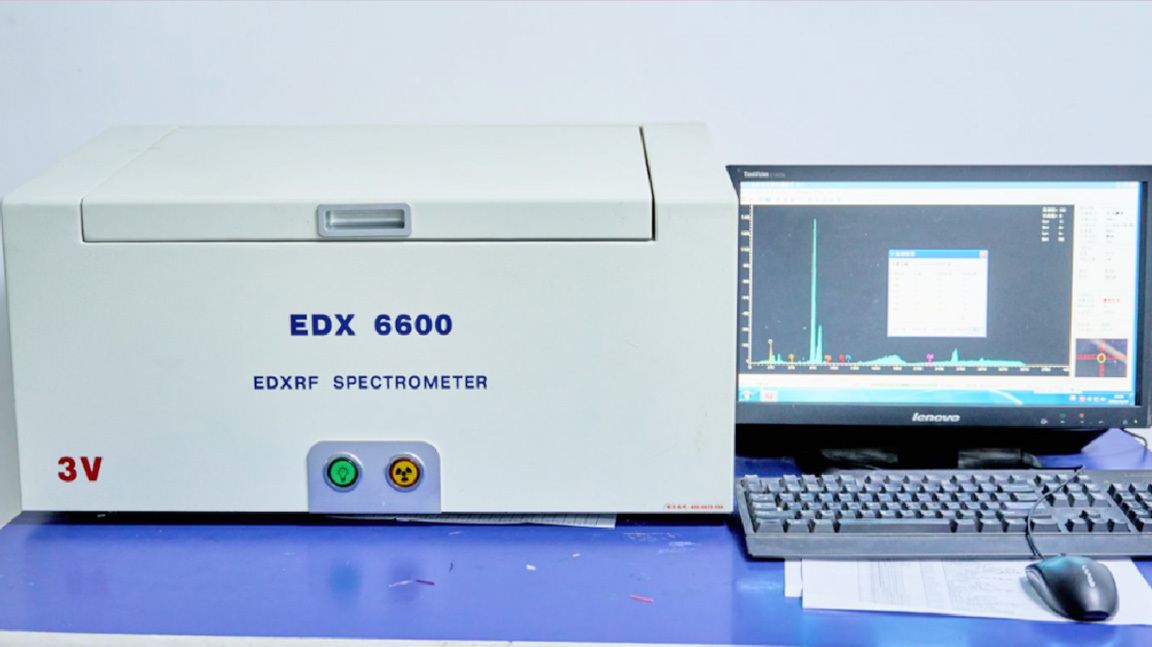

The company adopts international first-class raw materials, such as high-purity copper wires and high-quality insulating materials, to ensure that the conductivity and insulating properties of the products are optimized. Meanwhile, the company is also equipped with professional ROHS testing equipment to conduct strict environmental protection tests on all incoming materials to ensure that the products do not contain lead, mercury, cadmium and other hazardous substances, and meet international environmental protection standards.

With years of industry experience and strong supply chain integration ability, the company has established long-term and stable cooperative relationships with a number of high-quality suppliers. We are able to ensure the adequacy and timeliness of raw material supply, providing a strong guarantee for fast delivery.

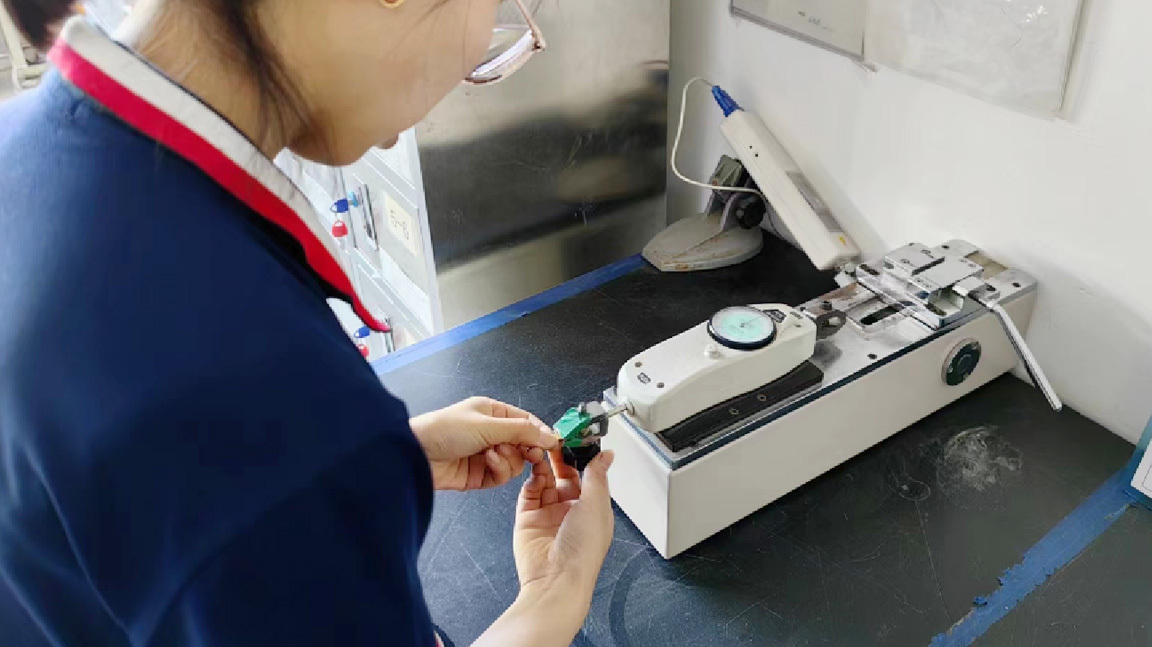

Terminal insertion and extraction force test

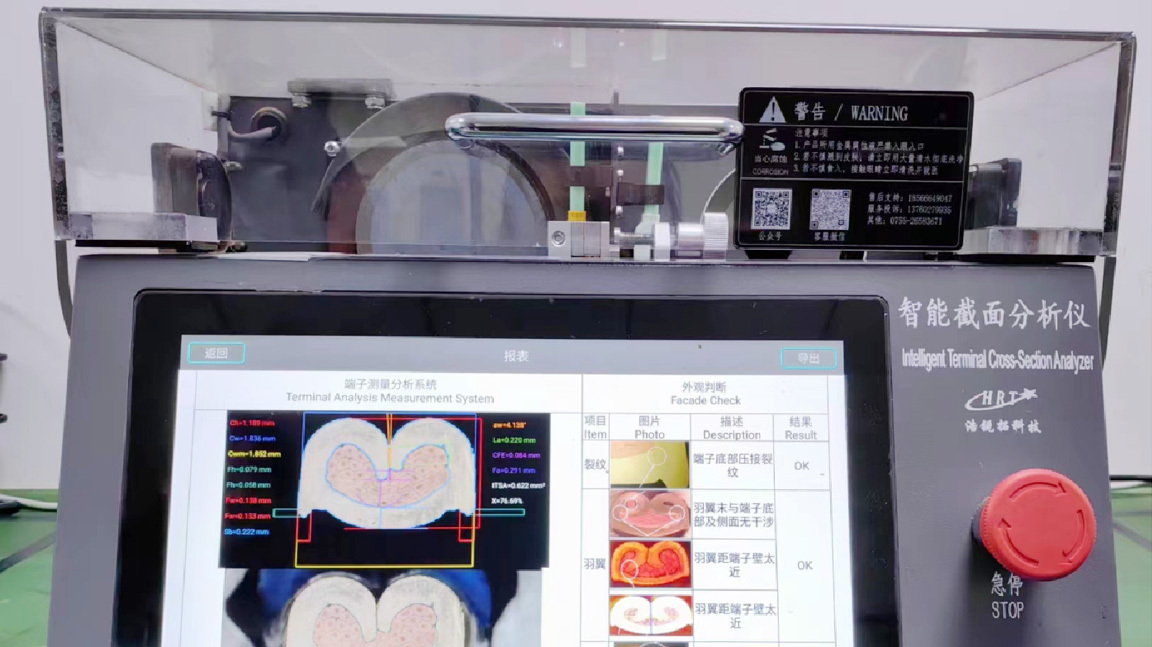

Terminal Cross Section Analyzer

ROHS Tester

Swing Tester

Terminal/Connector Selection Reliability

The company in the selection of terminals / connectors, not only consider the quality and performance of the product, but also consider the price, reputation and environmental protection and other factors, to choose the most suitable and cost-effective wire harness terminals for the customer, Therefore, in the selection of materials, imported materials we have long used are TE, JST, KET, MOLEX, STOCKO, JAM and other brands, to establish a long-term stable cooperative relationship with a number of high-quality suppliers For domestic materials, our cooperative manufacturers are FAF, CWB, HCB , ZUCH, etc. We provide our customers with safe and reliable quality and the best cost-effective goods.

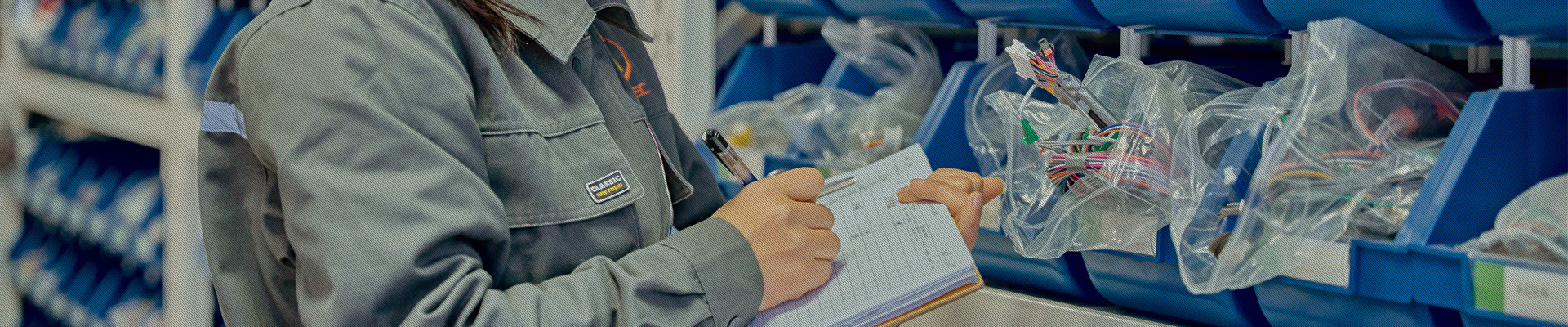

Reliability of product quality control management

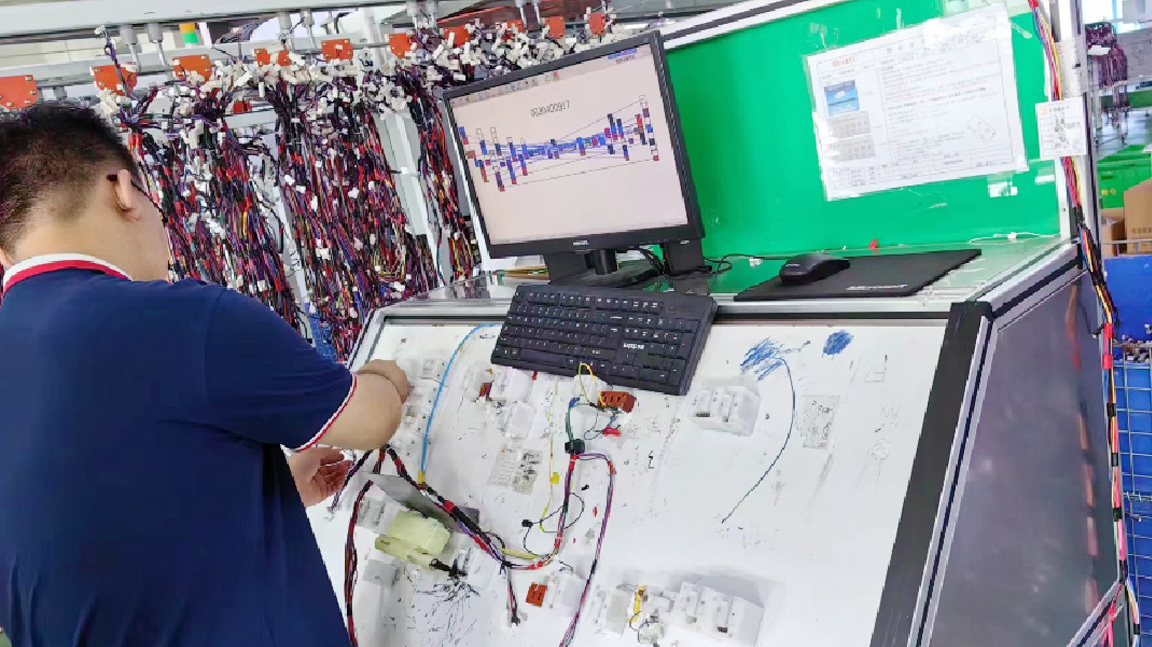

The company strictly implements the requirements of the quality system, and implements "7S" management on site. Each production line is equipped with an inspector, and the product process is strictly controlled in accordance with customer standards. In the pursuit of fast delivery, always adhere to the principle of quality first, we have established a strict quality control system, from the procurement of raw materials to the finished product delivery of each link are strictly controlled. We firmly believe that only high-quality products can win customers' trust and market recognition. Therefore, we always ensure the stability and reliability of the quality of our products while delivering them quickly.

Wire Sequence Detection

Conductivity Test

Terminal Crimp Inspection

Production process reliability

We constantly optimize the production process and improve the production efficiency. We introduce advanced production equipment and technology to realize automated and intelligent production, reduce manual intervention and lower production errors. At the same time, we have established a perfect production management system to ensure seamless connection between production links, so that the transformation of wire harnesses from raw materials to finished products is more rapid. At the same time, we have established a rapid response mechanism, once the customer puts forward the demand for shorter delivery time, we can quickly adjust the production plan to ensure on-time delivery.

After-sales service reliability

We have established a perfect after-sales service system to provide customers with a full range of technical support and solutions. Once customers encounter any problems or difficulties in the process of using, we can respond quickly and provide assistance. This kind of attentive after-sales service makes customers worry-free, and also wins a good reputation and credibility for us.