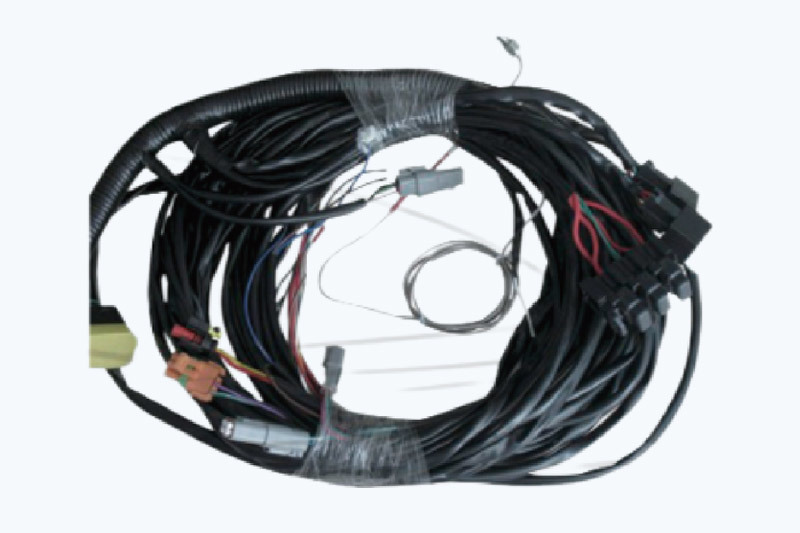

Automotive Wire Harness

In 2022, the subsidiary Xiangbian Energy obtained the IATF16949 quality management system certification, invested in 30 million to set up the automotive wiring harness division, the establishment of high-voltage new energy production line, vehicle wire harness production line, vehicle air conditioning production line. The introduction of the corresponding waterproof plug production equipment, new energy wire cutting equipment and electrical performance, air tightness testing station, etc., to ensure that high-quality products are provided to customers. At present, the cooperative automobile customers include: Haier Jiaozhou parking air conditioner, Beiqi Foton, Jiexin vehicle air conditioner, Xugong Machinery Road Branch, Qingdao Zhongqi Special Automobile Co., Ltd., etc.

Engine room

The wiring harness is used to connect the engine's electronic control systems, such as ignition, fuel injection and emission control.

Chassis

The wiring harness is responsible for controlling the brake system, suspension system and steering system.

Body

The wiring harness provides power and control signals for the lights, wipers, air conditioners, etc.

Dashboard

The wiring harness connects the speedometer, fuel gauge, instrument panel and other in-car electronic equipment.

Door

The wiring harness controls the door switch, window lift, door lock and other equipment.

security system

The wiring harness is connected to safety equipment such as airbags and seat belt pretensioners.

Infotainment system

The wiring harness provides power and control signals for car audio, navigation, reversing video and other equipment.

Comfort system

The wiring harness controls seat heating, ventilation, massage and other functions.

Diagnostic system for vehicle

The wiring harness is connected to a scan tool (OBD) to detect vehicle operating conditions and repair needs.

The characteristics of the automotive wire harness

The general characteristics of automotive wiring harnesses mainly include heat resistance, oil resistance, wear resistance, waterproof and dustproof, compact design, and good insulation. These features enable the car wiring harness to work stably in the complex internal environment of the car, ensuring that the transmission of current and signal is not affected.

Specifically, automotive wiring harnesses need to have the following characteristics:

1) Heat resistance: Automotive wire harnesses work in high temperature environments such as engine compartments, and high temperature resistant wires are required. For example, wires with a temperature resistance rating of 180 ℃ can be selected for engine compartment wiring harnesses.

2) Oil resistance: Since the automotive wire harness may be exposed to oil, the wiring harness material must have the ability to prevent oil and chemical corrosion.

3) Abrasion resistance: Frequently moving parts such as door harnesses require wear-resistant and flexible harness materials to adapt to frequent switching actions.

4) Waterproof and dustproof: The exposed wire harnesses such as the rear body wiring harness need to have good waterproof and dustproof performance to cope with bad weather and chemical erosion.

5) Compact design: Automotive wire harnesses need to be wired in a small space, and the design needs to be compact and easy to install and maintain.

Good insulation: The insulation layer of the wire harness needs to be thick to prevent short circuits and other electrical failures.

In addition, the structure of automotive wire harnesses is complex and delicate, usually composed of wires, connectors, terminals, sealing plugs, sleeves, fuses, clips, cable ties and other components. The selection and combination of these components ensure the stable operation of the wiring harness under harsh working conditions.

Automotive Wire Harness Solutions

Automotive wire harness solutions mainly include test solutions and optimization design.

1) Test solution: The automobile wire harness is a key component of the automobile circuit, which is responsible for the transmission and distribution of power and signals to ensure the normal operation of the vehicle. When selecting and applying low-voltage harness wires, it is necessary to consider conductivity, temperature and oil resistance, flexible pull resistance, insulation performance and cost to ensure the stability and reliability of the circuit. Aiming at the field of automotive wiring harness, a high-precision and fast-response test scheme is introduced, including high-current DC power supply and upper computer software, which can carry out test items such as voltage resistance, current resistance, durability, temperature rise, instantaneous overvoltage, instantaneous overcurrent, etc.

2) Optimized design: With the advancement of automotive technology, the traditional wire harness layout not only increases the complexity of the vehicle, but may also cause malfunctions. By building a unified, safe and reliable network environment, the vehicle network technology closely connects all kinds of equipment on the car, effectively reducing the use and management of wire harness. By integrating different systems, the in-vehicle network creates a simplified "bridge", eliminating scattered wiring harnesses, making information transmission more efficient, reducing the risk of failure, and ensuring the safety of data transmission and the internal system of the vehicle Normal operation.

Related Products