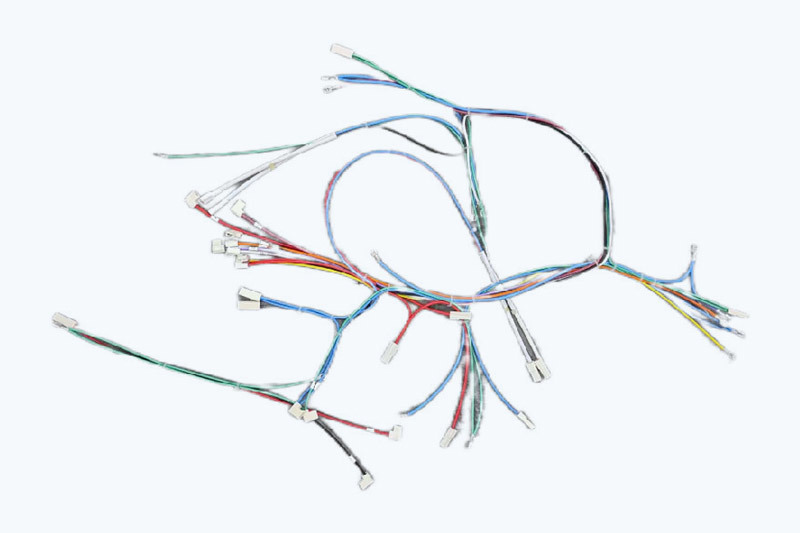

Wire Harness for Household Appliances

The home appliance wire harness products of Qingdao Heatec Electric Co., Ltd. are all self-made from copper wire drawing and winding to the final connector assembly. Subsidiary Xiangbian Energy has the production of 3C and UL series wire and cable qualification, through the national 3C product certification and the United States UL product certification, can meet the supply of some home appliance wire harness raw materials. Wire harness use terminal crimping machine, and with the mold for crimping, fine process.

In the selection of terminals/connectors, the company not only considers the quality and performance of the product, but also considers factors such as price, reputation and environmental protection, and selects wire harness terminals that are suitable for customers and have good cost performance. Therefore, in the selection of materials, we have long-term use of TE,JST,KET,MOLEX,STOCKO,JAM and other brands for imported materials, and have established long-term and stable cooperative relations with many high-quality suppliers. For domestic materials, our cooperative manufacturers include Jiade, Hexing, Changdecheng, Zhucheng, etc., to provide customers with safe, reliable and cost-effective products.

Heatec Electric Co., Ltd. has more than 10 years of wire harness inspection experience, from terminal crimping to conduction test and appearance inspection of the product, achieving 100 full inspection, and the qualified rate of one-off line reaching 99.95. In the field of home wiring harness, with excellent strength, products throughout the entire field of home appliances, such as water heaters, water boilers, dishwashers, small appliances, washing machines, air conditioners, refrigerators and freezers. For the home appliance industry to provide from external connectors, cables to internal connectors, cable system interconnection solutions. Our connected product solutions have a dominant position in China's home appliance industry, achieving a market share of nearly 20% and ranking in the top 5 in the market for many years.

Refrigeration appliances

It is used to connect compressors, thermostats and other components to ensure the normal operation of the refrigeration system.

Air conditioning equipment

It is used to connect motors, fan controllers, etc. to achieve air conditioning and ventilation functions.

Clean electrical appliances

Used to connect motors, heating elements, etc. to ensure the normal operation and operation of the equipment.

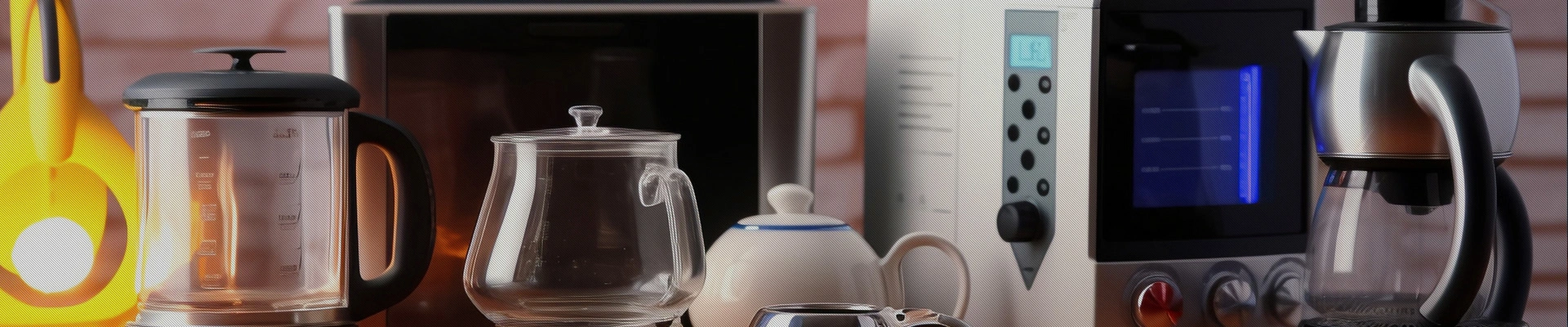

Kitchen Appliances

Used to connect heating elements, control panels, etc., to achieve cooking functions.

Electric Heater

Connect heating element and controller to provide heating function.

Alarm, bell and other electrical appliances

Used to connect sensors and control circuits to achieve alarm and control functions.

The characteristics of the appliance wire harness

1) Standard plug: easy to connect and disconnect, suitable for household voltage use.

2) Moderate wire diameter: suitable for household voltage use to ensure the normal operation of the equipment.

3) Safety certification: such as UL, CE and other standards to ensure user safety.

4) Additional protective measures: such as rubber sheath to prevent wear.

Wire Harness Solutions for Appliances

The wire harness solution for household appliances mainly includes three aspects: design optimization, manufacturing process improvement and quality control enhancement.

3.1 design optimization

1) Simplify the number of wiring harnesses: By reasonably planning the wiring harness path, reduce the cross and interference between the wiring harnesses, and make the wiring harness layout more concise and clear; 2) Modular design: organically integrate the wiring harness with other parts of the refrigerator to improve the overall structure Compactness and aesthetics.

3.2 manufacturing process improvement

1) Adopt advanced production technology: such as automated production lines and precision processing equipment to ensure the accuracy and quality of the wiring harness;

2) Strengthen quality control: Implement strict quality inspection standards to avoid the outflow of unqualified wiring harness products and ensure the safety and reliability of the wiring harness.

3.3. Quality Control

1) Establish a complete quality management system: clarify the quality control requirements of each link to ensure that every link from raw material procurement to production, testing, and packaging is effectively monitored;

2) Employee training: Strengthen the quality awareness training of employees and improve the enthusiasm and initiative of all employees to participate in quality control.

Related Products