Energy Storage Equipment Wire Harness

In recent years, in the context of carbon neutrality, policies have strongly supported clean energy and development-driven energy storage requirements. Therefore, the energy storage industry, photovoltaic industry high-speed development, including new energy storage batteries, mobile commercial energy storage, household small energy storage equipment, peak and valley price difference distribution storage. Our company also actively responds to the national policy, promotes "0" carbon, green energy, and actively promotes negotiations with Ningde Times and Guoxuan Gaoke, the cutting-edge customers on the energy storage track. Establishing a high-pressure new energy production line. The introduction of the corresponding new energy wire cutting equipment and electrical performance, air tightness testing station, etc., to ensure that high-quality products are provided to customers.

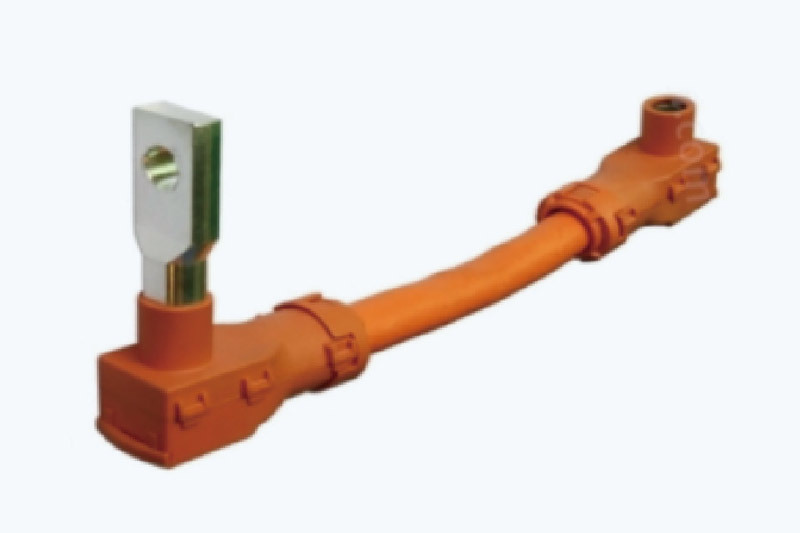

High voltage energy storage wire harness

The high-voltage part used to connect the battery pack and the electric drive system usually needs to withstand high voltages of hundreds of volts, with good insulation performance, high voltage resistance and anti-corrosion performance.

Low voltage energy storage harness

Used to connect the battery pack and low-voltage electronic equipment, such as battery management system, motor controller, etc., having good conductivity and anti-interference ability.

Communication wire harness

Used to connect the battery pack to the vehicle's communication system to ensure reliable transmission of information such as battery status monitoring, fault diagnosis, and charging control.

Characteristics of energy storage wire harness

The characteristics of the energy storage equipment harness produced by our company mainly include the following aspects:

1) High flexibility and bending resistance: The energy storage harness adopts high flexibility cable material, which can be easily bent and adjusted in a narrow space to adapt to the environment with limited energy storage battery space.

2) Acid and alkali resistance and aging resistance: The insulating layer and sheath layer of the energy storage harness use high-performance cross-linked polyolefin materials. After "irradiation cross-linking" treatment, it has good acid and alkali resistance and aging resistance. Ensure that it can still maintain good working condition in harsh environments.

3) High and low temperature resistance: The wire harness uses low-smoke halogen-free, high-efficiency flame-retardant materials, and the temperature resistance range is -40 ℃ to +125 ℃, even in severe cold or high temperature environments, it can maintain stable performance.

4) Large current conduction capacity: The energy storage harness uses oxygen-free pure copper material, which has good conductivity and stability, and can meet the needs of high-power energy storage systems.

5) High insulation performance: The wiring harness uses high insulation and environmental protection plastic as the insulation and sheath layer material, which has been strictly tested to ensure good insulation performance and safety.

6) Environmental adaptability: The energy storage harness has excellent battery acid resistance, coolant resistance, high temperature resistance, low smoke, flame retardant and environmental protection characteristics, and adapts to various harsh environments.

7) High current carrying capacity and electromagnetic compatibility: The energy storage harness can handle high current, reduce power loss, and adopt anti-EMI and RFI design to avoid affecting other electronic equipment.

8) Safety performance: The wiring harness conforms to UL, ISO and other standards, and has safety features such as overload protection and short circuit protection.

9) Environmental protection: The wire harness meets environmental protection requirements such as RoHS and REACH, reflecting the concept of sustainable development.

Energy Storage Harness Solutions

The solution of energy storage wire harness mainly includes the following aspects:

1) Choose high temperature resistant materials: Choose high temperature resistant wire materials, such as silicone wire, XLPE wire, etc., these materials can withstand higher temperatures without losing insulation performance. The connector and sheath are made of high temperature resistant plastic or metal materials to ensure good mechanical strength and insulation performance in high temperature environment.

2) Heat dissipation design optimization: Consider adding fans, heat sinks, heat pipes and other heat dissipation devices in the wiring harness layout design to improve the air circulation inside the system and reduce the working temperature. Reasonably plan the wiring harness direction and equipment layout to avoid heat concentration and reduce the influence of wiring harness heating.

3) Fire retardant design: the use of good flame retardant materials, in the structural design of the harness to add flame retardant layer, improve the overall fire performance.

4) Application of temperature sensor: Install a temperature sensor in the key part of the energy storage system to monitor the temperature of the wiring harness in real time. Once the safety range is exceeded, the system can automatically alarm and cut off the power supply to prevent overheating accidents.

5) Built-in multi-layer safety protection mechanism: including dust-proof and waterproof design, short-circuit protection, etc., strictly follow international safety standards to ensure that each energy storage harness can operate safely and stably in complex environments.

Related Products